Load Planning: How Load Planers Can Use Route Optimization to Reduce Transportation Costs

Making the most of your freight vehicles and drivers is a constant challenge for all trucking companies, large and small.

And that’s especially important in an economy where the competition on price is increasing all the time. In 2019, increasing price pressure from competitors was a significant challenge for 41% of trucking companies and 38% of shipping companies.

Load planning, when done right, can help you to compete on price.

It can help lower your mileage, improve your delivery capacity, and (ultimately) reduce your overhead and increase your profit margins.

In this article, we’ll dive into what load planning is, what it can do for your company, and the best ways to implement it in 2020.

What we’ll cover:

- What Is Load Planning?

- 4 Primary Responsibilities of a Load Planner

- The Problem With Traditional Load Planning

- 8 Benefits of Combining Load Planning With Route Optimization

- Load Planning FAQ

- Combine Load Planning and Route Optimization With OptimoRoute

What Is Load Planning?

Load planning in transportation is the process of consolidating cargo to maximize the capacity of each truck and driver so that multiple shipments can be delivered in the fewest number of vehicles. The aim of load planning is to reduce the number of vehicles on the road (and therefore transportation costs) while improving operational efficiency.

But it’s not as simple as squeezing the maximum number of pallets into a container. You need to consider the vehicle’s specifications (refrigeration, for instance), center of gravity, destinations, type of product, and much more.

4 Primary Responsibilities of a Load Planner

Your business’ load planner has the responsibility of improving the efficiency of your entire operation. Maximizing the capacity of your fleet is the key to more efficient outbound logistics, reduced overhead, and bottom-line business growth.

That being said, there are four primary responsibilities that are higher priority than others.

1. Maximize the capacity of each truck and driver

The primary task of a load planner is consolidating cargo to maximize payload capacity: load planners must be able to optimize by mixing and matching loads based on cargo type, destination, size, and vehicle capacity.

For example, they have to mix larger packages with smaller loads for optimal space utilization while also considering the destination of each package (when it’s unpacked), the weight and balance, giving sensitive cargo the protection it needs, sharing loads between drivers and more.

They also have to consider whether palletized cargo is the right choice or whether to use a different loading process.

All this, and more, to ensure that each shipment safely reaches its destination on time.

2. Comply with regulations

35% of truckers find complying with new regulations an ongoing challenge. With a sophisticated load plan that considers vehicle characteristics and not just basic capacity, you can ensure compliance for all your trucks and loads.

If only a few trucks are refrigerated or certified to ship non-radioactive hazardous material (NRHM), you have to balance all relevant loads between them.

In addition to that, when you load orders into a truck, you effectively commit that truck and driver to a certain workload. If the load planner underestimated the required time, the driver would face a choice between violating hours of service (HOS) regulations or delivering a load behind schedule.

3. Cut unnecessary costs

It’s not just about squeezing as much cargo into a single truck as possible. A load planner should also consider factors like loading sequence, destinations, driver overtime, and more.

Bad load planning leads to more trucks and drivers than required in action at any given time. Unforeseen delays can also cause shipments to need to be repeated, which causes additional mileage, overtime, and more.

4. Create productive partnerships

As an LTL carrier, if you want to expand your business to new routes, a single ongoing contract probably won’t be enough.

By partnering with other trucking companies that cover the new area, you can expand your operations and increase revenue without the ability to send a fully loaded truck on a route.

The Main Problems with Traditional Load Planning

Even combining similar loads to a single location is complicated when you have different deadlines and truck capacities.

With a variety of clients, destinations, and cargo with different requirements and regulations, it’s an impossibly complex task. Doing everything manually is not a good idea.

Manually planning and sequencing orders is time-consuming

There are a lot of factors to consider, from cargo requirements and vehicle characteristics to how you group destinations together. With a traditional, manual approach to delivery route planning, you end up with a lot of operational overhead.

Even in a mid-sized company, you probably need multiple people on the job, especially if you still rely on older solutions, or worse, Excel spreadsheets.

Failure to consider driver workloads and overtime

A traditional approach and old load planning systems don’t factor in other expenses like driver overtime and workloads. That means you have to manually audit and adjust any generated plan.

Manually planned routes are inefficient

Even if you have a dedicated team planning your routes, these routes are rarely efficient. Your drivers will spend unnecessary working hours and gas by following these directions.

8 Major Benefits of Combining Load Planning With Route Optimization

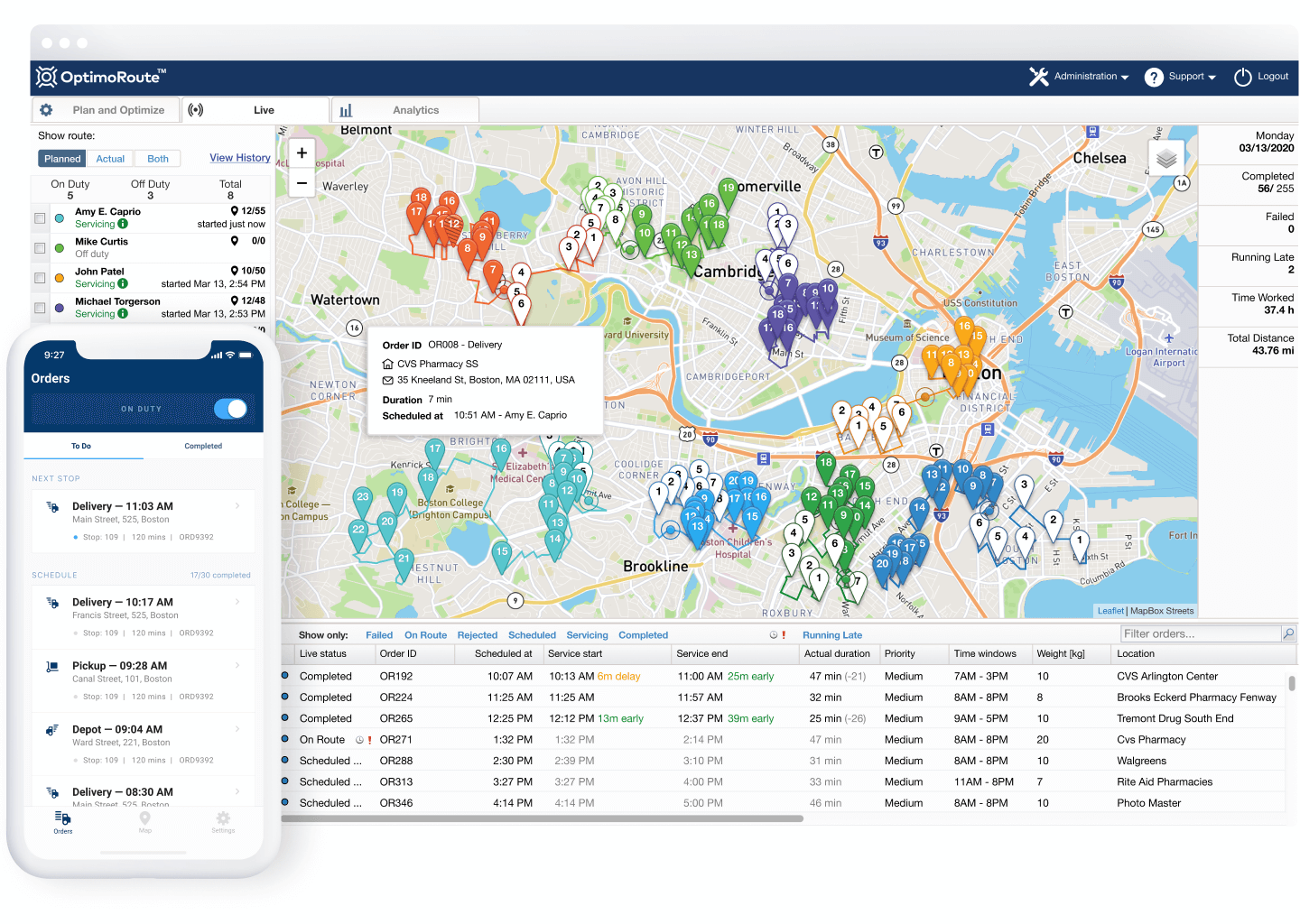

Instead of handling load planning and route optimization separately with different tools and spreadsheets, your company will see the biggest ROI by combining both.

1. Increased delivery capacity

By combining load planning with route optimization, you get the benefit of increasing the efficiency of your routes and always loading the right cargo in the ideal order.

Before using OptimoRoute, Hardie’s Fresh Foods struggled with maximizing the capacity of their fleet. After making the switch, more efficient planning and route optimization helped them improve their delivery capacity by 14% — an extra 330 loads every single day.

The new functionality and planning process allows them to handle higher demand without increasing their fleet or workforce.

2. Less Labor Hours

No more manual number crunching is necessary for mapping out the most efficient delivery route or picking the right truck and driver for a load.

Bee Imagine, a third-party logistics (3PL) provider based in Southern California, uses OptimoRoute to cut down on labor costs, and quickly adjust to last-minute orders and instructions from clients.

“This software will cut down on labor hours considerably. We’d had issues with our client sending the list of stops late at night, requiring planners to accumulate overtime as manual routing took up to 4 hours”. – Luis Flores, Bee Imagine

Reduce your operational costs by 30%

Increase delivery capacity by 43%

Plan 7x faster

3. Lower shipping and delivery costs

Fewer vehicles and drivers on the road for a shorter amount of time mean significant cost-savings per load and higher profit margins.

Hardie’s Fresh Foods reduced total mileage by 20% and also saw a 12% reduction in driver-related costs after switching to OptimoRoute.

4. Fewer stops

By taking a holistic approach to optimizing your routes and loads, your drivers can unload their cargo load in fewer stops.

5. Quicker delivery

With the shortest possible routes and fewer stops, you can deliver your cargo quicker without breaking any rules or regulations.

6. Positive customer experiences

Faster shipments at no extra cost mean that you make your customers happier, and potentially retain them for longer without having to compromise on price.

7. Reduced overtime and more balanced workloads for divers

By effectively distributing the workload, you can reduce overtime costs and provide a healthier working environment to your drivers.

OptimoRoute’s workload balancing feature automatically distributes the number of shipments based on current working hours, scheduled deliveries, and more.

Our weekly planning and multi-day long-haul routes support lunch breaks, mandated driving breaks, delivery windows, and minimizes overtime.

8. Increased profitability

In an industry where competing on price is a fact of doing business, lowering your delivery and operational costs is a must to protect your profit margins while keeping your customers.

More efficient loading and routing make a tremendous difference — reduced mileage and driver costs combined with increased delivery capacity mean much healthier profit margins. You can offer competitive prices and win new business without sacrificing profitability.

Load Planning FAQ

Below, we answer some of the most frequently asked questions about load planning and related topics.

What does a load planner do?

A load planner works to optimize all aspects of the transportation process. A load planner’s job is to maximize loads per truck, expedite routes, and reduce shipping time. A load planner also ensures that delivery is made to the customer in the most cost-effective way.

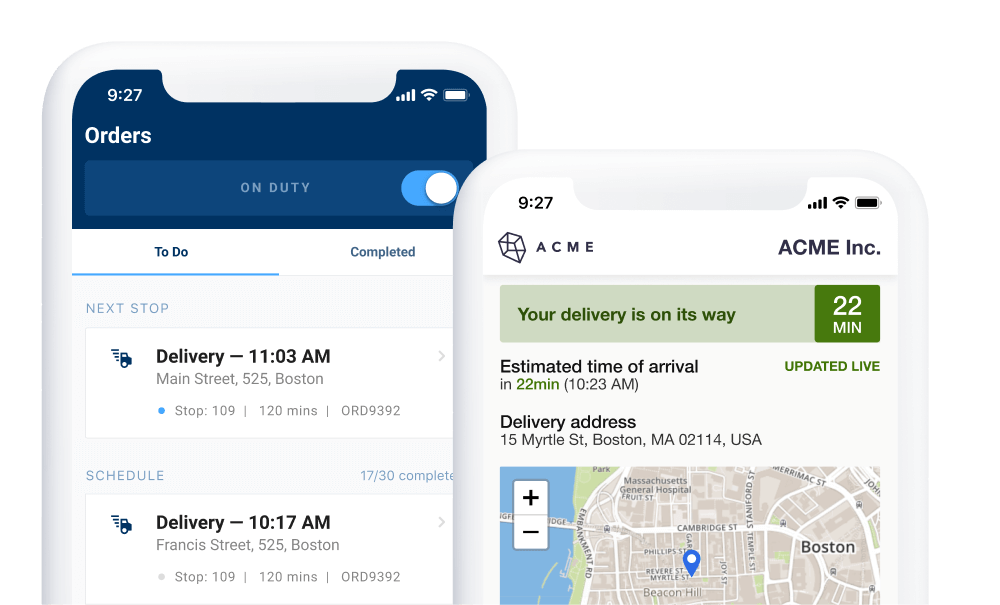

What is load planning software?

Load planning software is a tool that lets operations managers and small business owners plan what items or units belong in which trucks and routes without any manual calculation.

With much less work, it ensures that every truck carries the ideal truckload when it leaves the loading dock. Using a solution that interacts with your warehouse management system can streamline your process even further.

What is load optimization?

Load optimization is the art of optimizing the specific loads in each vehicle, typically with the help of a dedicated software tool. Modern systems can consider millions of factors from vehicle capacity and characteristics, to individual load requirements, and destinations.

Because software is a key component of load planning these days, the terms load planning and optimization are used interchangeably by logistics experts and software providers.

What is a load tender?

A load tender is a negotiable offer of cargo or pick-up-request issued from a shipper to a carrier. It includes all necessary details like delivery numbers, freight terms, dock times, and more.

The term is primarily used in the motor industry.

Combine Load Planning and Route Optimization With OptimoRoute

Even when done in a vacuum, load planning and optimization can have a significant impact on the freight cost of shipping your goods. It makes sure that your LTL loads are distributed more effectively across a lower number of trucks.

But if you genuinely want to take your trucking business into the 21st century, you need to centralize your data. By combining loading planning and route optimization, you can make sure that all your loads are shared and sequenced out based on the ideal route for each truck.

You can also better manage your workforce with workload management tools, real GPS routes, and long-haul multiple-day truck route planning and tracking.

To see for yourself just how OptimoRoute can help transform your business, you can test our software free for 30 days with no obligation.

Try OptimoRoute™ for Free

No installation or credit card required